Why Is My Boiler Losing Pressure? & How To Fix

Dec 26, 2025

When your boiler keeps slipping under 1 bar, it’s easy to feel unsure about what’s going on.

Some pressure loss is completely normal, while other cases point to leaks or component faults that need attention. Telling the difference isn’t always straightforward.

We’ll break down the reasons your boiler might be losing pressure, the checks you can safely do at home, and the situations where getting a professional involved will save you time, money, and unnecessary disruption.

Key Notes

Common causes include system leaks, air ingress, and faulty pressure-control components.

DIY checks help distinguish normal fluctuation from faults requiring professional diagnosis.

Non-invasive detection tools pinpoint hidden leaks without damaging floors or walls.

Stable cold pressure of 1.0–1.5 bar indicates a healthy, well-balanced system.

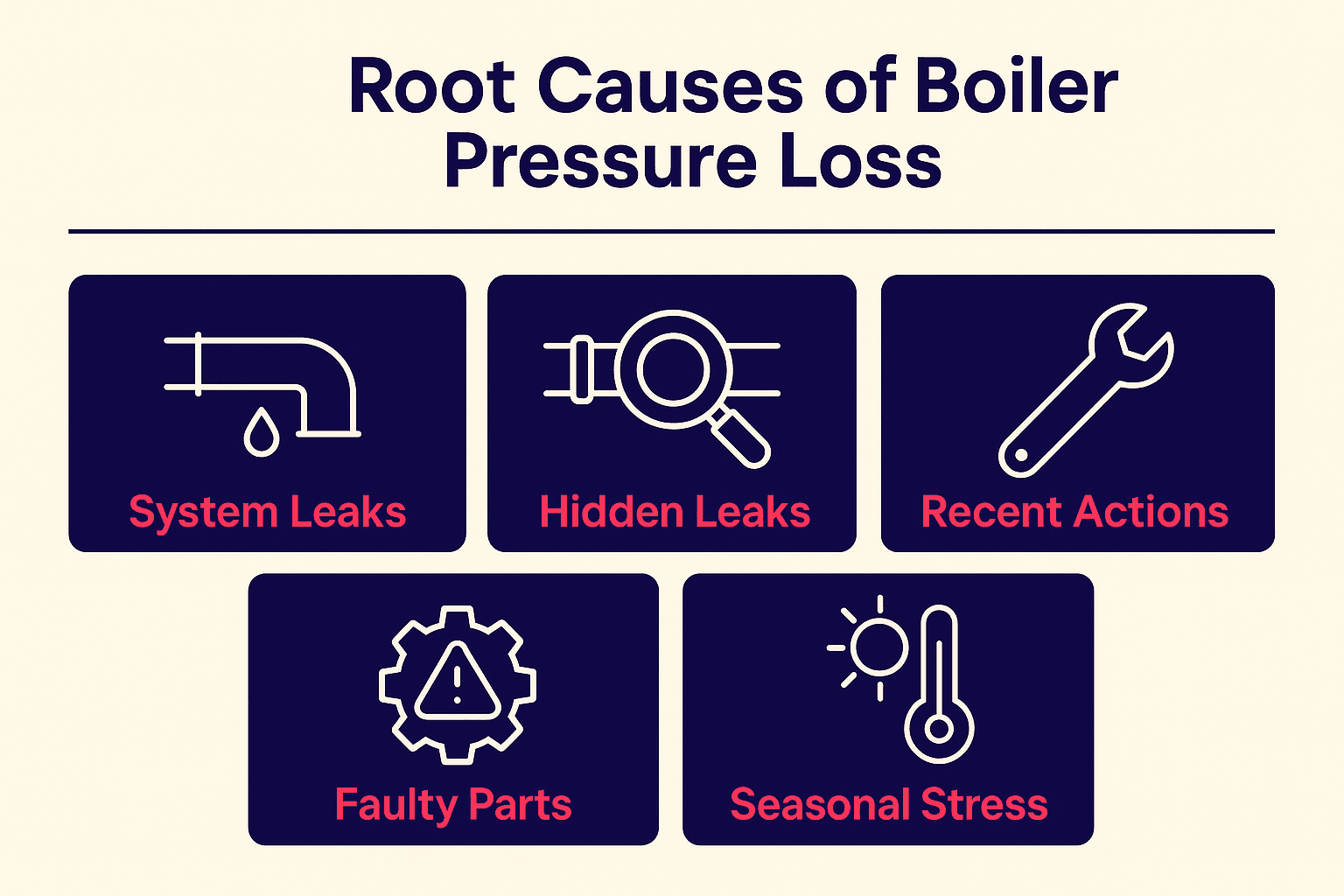

Boiler Losing Pressure: Causes Overview

A sealed heating system should sit around 1.0–1.5 bar when cold and rise to roughly 1.5–2.0 bar when hot.

If your pressure keeps falling, the usual culprits are:

A system leak, visible or hidden

Recent radiator bleeding or air in the system

A component fault such as the expansion vessel losing charge or a passing pressure relief valve (PRV)

Safe First Steps:

Check the gauge cold, look for obvious damp, confirm the filling loop is fully closed, and repressurise to about 1.2 bar cold.

If pressure keeps dropping daily or you see spikes above 2.5 bar when heating, stop DIY and bring in a Gas Safe engineer or a leak detection specialist.

Is The Drop Normal Or A Fault?

Not every dip means disaster. Here is a simple way to classify it:

Normal Fluctuation: You bled radiators recently and saw a small one-off drop that disappeared after a single top-up. No repeat over days.

Minor Issue Developing: You need to top up every couple of months. Keep an eye on it and consider a service.

Likely Fault: You top up weekly or daily, or the gauge falls soon after repressurising. That points to a leak or a failing component.

Urgent: Pressure plummets to zero within 24 hours or spikes high when hot, then drops low when cold. Stop DIY and call a professional.

A useful habit is to record cold readings daily for three to five days. Linear, steady falls usually point to a leak. Erratic highs and lows often implicate the expansion vessel or PRV.

Root Causes Mapped

1. System Leaks You Can See

Weeps at radiator valves and towel rails

Drips on visible copper or plastic runs, elbows, olives, and compression joints

Damp below the boiler case or around the filling loop

Signs of corrosion, rust stains, white powdery residue

2. Hidden/Micro-Leaks

Pipework under floors, behind plasterboard, or buried in screed

Under kitchen units and bathrooms where small weeps soak into timber

Internal boiler components, such as heat exchangers, that seep into condensate

3. Recent Works & User Actions

Radiator bleeding naturally lowers pressure. Top up immediately afterwards.

Filling loop left slightly open can cause confusing fluctuations. Close both valves firmly.

Bathroom or plumbing works can introduce air. Systems often settle after a thorough bleed and top-up.

4. Component Faults

Expansion vessel lost charge or diaphragm failure. You may see high hot pressure and low cold pressure.

Pressure relief valve (PRV) passing to the discharge pipe. A small, constant loss is common.

Auto air vent weeping on the boiler or near the pump.

Pump seals or a faulty pressure gauge giving false readings.

5. Operating and Environmental Factors

Cold snaps leading to frozen condensate or external pipework. Thawing can temporarily fix symptoms, but knock-on pressure issues remain.

High cycling in winter that stresses weak points and speeds up small leaks.

Sludge or low inhibitor levels that accelerate corrosion and pinholes.

Safe DIY Checks & Fixes for Homeowners

You can do the basics safely. Work with the system cold and take your time.

1. Start With A Visual Sweep

Look around the boiler, visible pipes, and all radiators. Use a torch. Check valve tails, towel rails, and any recent work areas.

Powdery white deposits or green verdigris often point to slow weeps.

2. Paper Towel Test

Place dry paper under the boiler and under suspect valves. Leave for a few hours. Staining confirms micro-drips.

3. Confirm The Filling Loop Is Fully Closed

Many pressure mysteries come from a slightly open valve or a loose braided hose cap. Close both valves tightly after topping up.

4. Repressurise Correctly

With the boiler off and cool, open the filling loop slowly until the gauge reaches about 1.2 bar cold. Close both valves. Turn the system back on.

5. Bleed Radiators Properly

If you hear gurgling or have cold spots at the top, bleed each radiator with a towel below the valve. After bleeding, repressurise back to 1.2 bar cold.

6. Log Cold Readings For 3–5 Days

Record pressure at the same time each day with the heating off. Linear falls suggest leaks. Erratic highs and lows suggest the vessel or PRV.

7. Simple Isolation Test (If Your Setup Allows)

Some systems let you isolate the boiler from the heating circuit.

If pressure holds when isolated, the leak is likely in the radiators or pipework. If it still falls, the issue may be within the boiler or its immediate components.

If you are unsure, skip this step and call a professional.

8. Trust Your Senses

Listen for hissing or dripping near pipe runs. Sniff for musty odours near skirting boards. Check for bubbled paint or hairline cracks with discolouration.

When To Stop DIY & Call A Professional

Safety first. Bring in a Gas Safe-registered engineer or a specialist if any of the following apply:

Daily or weekly drops despite topping up

A full drop to zero within 24 hours

High hot pressure, then low cold pressure

Visible leaks, corrosion, mould, or bubbling paint

Boiler error codes, lockouts, banging, or persistent gurgling

Gas smell or carbon monoxide alarm. If you suspect a gas emergency, call 0800 111 999 immediately.

Professional help avoids unnecessary damage and gets you from guesswork to certainty.

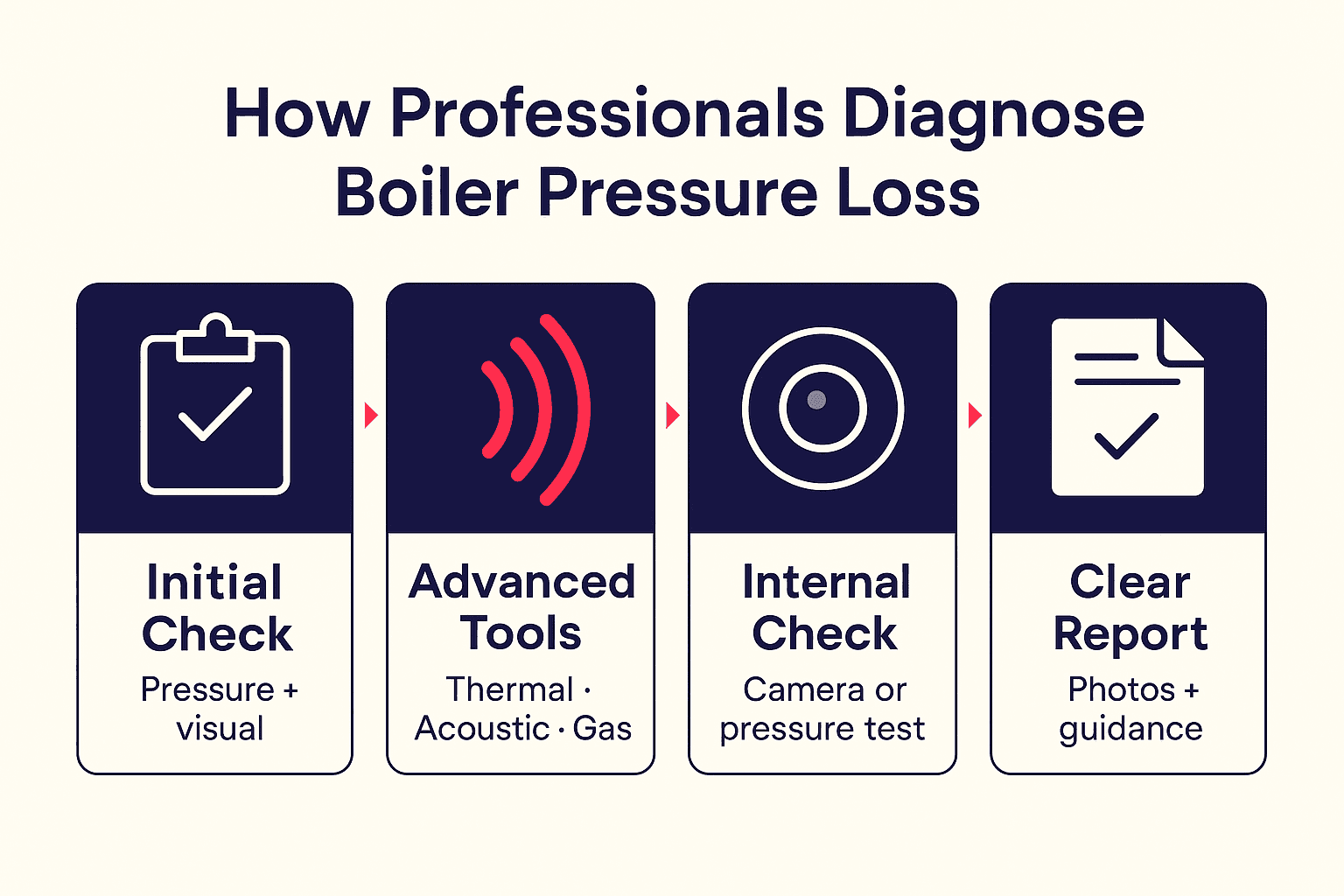

How Professionals Diagnose Non-Invasively

At London Leak Detection, we prefer brains and instruments over holes in your home. A typical visit follows a structured flow:

1. Initial Assessment

Gauge and log the pressure behaviour

Visual inspection of accessible pipework, valves, and radiator tails

Section tests or temporary isolation to narrow down zones

2. Advanced Diagnostics

Thermal imaging to reveal heat signatures of water movement under floors and behind walls

Acoustic listening to pick up hiss and drip signatures through solid surfaces

Tracer gas (harmless hydrogen mix) injected into the system that escapes at leak points and is detected from above with a sensitive probe

3. Internal Confirmation

Endoscopic cameras into voids and behind panels

Targeted pressure tests on isolated loops or manifolds

4. Reporting & Guidance

Clear photographs, locations, and cause

Insurer-ready report with recommendations for repair and prevention

Our methods are non-invasive wherever possible. We protect finishes and only open what we must.

Fix Options By Cause

Once the source is confirmed, fixes are straightforward and proportionate.

Leak Repairs

Re-make or replace leaking radiator valves, olives, and fibre washers

Replace short pipe sections with pinholes or corrosion

Address heat exchanger seepage with manufacturer-approved parts

Expansion Vessel and PRV

Recharge vessel to the correct pressure or replace if the diaphragm has failed

Replace PRV if it is passing, then flush and recommission the system

Air and Sludge

Full bleed and balance after works or power interruptions

Chemical clean if sludge is present, install or service a magnetic filter

Dose with corrosion inhibitor to slow future issues

Controls and Sensors

Replace faulty pressure gauges or autos vents that are weeping

Verify pump seals and circulation behaviour

You should always see the system return to a steady 1.0–1.5 bar cold and hold that over days after a proper fix and recommission.

Costs, Timeframes & Disruption

Detection:

Our £490 fixed day rate covers up to four hours of professional, non-invasive diagnostics.

No Find, No Fee means exactly that. If we do not locate the leak, you do not pay for detection.

Documentation:

You receive an insurer-approved report with images and findings to support claims.

Repairs:

We give transparent options and pricing before any work, and we only proceed with your approval.

Guarantee:

Our 12-month leak-free guarantee covers you for the same leak reappearing after our detection and recommended repair.

Availability:

Same-day and weekend appointments are often available across Greater London.

Prevention & Seasonal Care

A little care goes a long way toward stable pressure:

Annual service: Have a Gas Safe engineer check the expansion vessel charge, PRV function, and overall system health.

Inhibitor and filtration: Maintain corrosion inhibitor levels and clean magnetic filters to protect pipework and radiators.

Pipe lagging: Insulate vulnerable pipework and the condensate line before cold snaps to avoid freezes and knock-on pressure weirdness.

Monthly glance: Check pressure cold once a month. If you keep a quick log, you will spot trends before they become issues.

Before winter: Bleed radiators and set cold pressure around 1.2–1.3 bar for multi-storey homes where a touch more head helps.

Special Situations Explained

Combi vs System Boilers

Combi boilers are more likely to show pressure issues because the sealed circuit serves both heating and hot water. System and heat-only boilers may hide symptoms in separate components.

Diagnosis is similar, but access points vary.

Underfloor Heating

UFH manifolds and loops add joints and actuators that can weep invisibly into screed. Thermal imaging and tracer gas are particularly effective here.

Flats and Tall Properties

Where the system rises across several floors, you may set the cold pressure a touch higher after professional advice. The aim is a consistent radiator fill without over-stressing components.

Oil Boilers in the UK

Traditional open-vented oil systems behave differently from sealed gas combis. Pressure behaviour is less of a focus, but leaks, sludge and PRV health still matter.

If you have an oil combi, treat pressure exactly as you would with a gas combi and follow the same steps.

Need Certainty About Your Pressure Loss?

Pinpoint the issue quickly with zero hidden costs.

Frequently Asked Questions

Can low boiler pressure increase my energy bills?

Yes. When pressure is low, radiators heat unevenly and the boiler works harder to achieve the same temperature. This leads to longer run times and wasted energy until the underlying issue is fixed.

Does turning the heating off for long periods cause pressure loss?

Extended inactivity can allow air to enter the system or let small weeps go unnoticed, leading to gradual drops. It is worth checking pressure before restarting the heating after long breaks or holidays.

Could my thermostat or controls cause pressure issues?

Not directly, but faulty controls can lead to over-cycling, which puts extra strain on the expansion vessel and PRV. If pressure drops coincide with inconsistent heating cycles, controls may need checking.

Is it normal for pressure to drop after a power cut?

Yes, sometimes. Restarting the boiler after a power cut can shift trapped air or unsettle older components, especially pumps and auto air vents. A small one-off drop is fine, but repeated drops indicate a fault.

Conclusion

Most issues come back to the same themes: a leak somewhere in the circuit, trapped air from recent work, or a component that is no longer doing its job. If your boiler is losing pressure regularly, the real priority is figuring out why it’s happening, because topping up only masks the symptom.

Logging readings, checking simple things like the filling loop and radiator valves, and knowing the difference between a normal dip and a genuine fault puts you in control long before a professional steps in.

And if you do need expert help, non-invasive detection takes the guesswork out of the whole situation and protects your home from unnecessary disruption.

If you’d like clear answers without hidden costs or invasive work, get a free quote. It’s a straightforward way to get accurate detection, insurer-ready reporting, and a plan that solves the issue rather than chasing it.